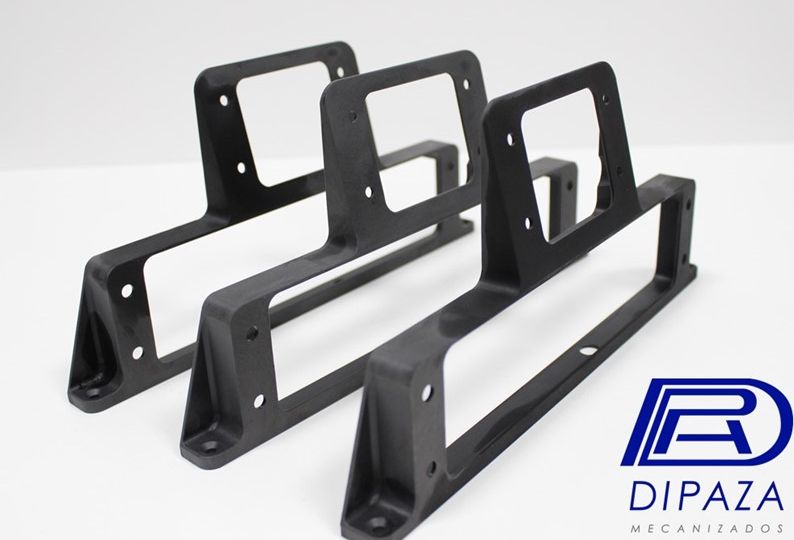

TECHNICAL PLASTICS.

PAI

- Polyamideimide has high resistance to high temperatures and is capable of performing under severe conditions. PAI machined parts provide greater compressive strength and higher impact resistance than most advanced engineering plastics.

PBT

- Polybutylene terephthalate is a thermoplastic from the family of polyester polymers. It is characterized by its high strength, rigidity and resistance to thermal deformation, as well as by its very high dimensional stability and little tendency to creep. The PBT polymer is especially suitable for food industry applications due to its excellent resistance to chlorine and caustic cleaning solutions.

PC

- Polycarbonate shows high stiffness and extreme impact resistance. It has high mechanical and diamond resistance and has high dimensional stability.

PEEK

- Chemically resistant and insoluble in common solvents including acids, salts and oils. Good dimensional stability at high temperatures (important due to its industrial applications). Its modulus of elasticity is strongly influenced by its degree of crystallinity; Due to its viscoelastic nature, depending on the temperature different tensile strength values are obtained, polyetheretherketone (PEEK) is lighter than steel, aluminum and titanium. PEEK ™ is sterilizable in autoclave, by application of ethylene oxide or by radiation and exhibits remarkable resistance to radiation.

PET-P

- Polyethylene terephthalate-based polyester is a semi-crystalline thermoplastic with excellent dimensional stability and resistance to wear and moderate acid solutions. Its high melting point allows PET-P to retain significantly more of its original strength than nylon or acetal, making it suitable for manufacturing precision mechanical parts. Its low moisture absorption allows the mechanical and electrical properties to be practically unaffected by moisture.

PI

- Polyimide stands out for its characteristics of strength, dimensional stability and resistance to creep even at high temperatures. Its low wear index together with the ability to work without the need for lubricants make PI the ideal material for applications subject to high demands on friction and wear, prolonging the useful life and reducing maintenance costs.

POM

- Polyoxymethylene shows good sliding properties, electrical insulation and high resistance to wear.

- It has high thermal stability, resistance to solvents and stress cracks

- Its main applications are: bearings, accessories, sprockets, screws and parts for the textile industry.

PPS

- Linear polyesulfide offers very high mechanical capacity, thermal and chemical resistance, high dimensional stability, and creep resistance.

- The PPS belongs to the highest of the Polymers. By reinforcing with glass fibers, resistance is achieved, comparable with light metals. PPS bridges the gap between technical synthetics and PEEK with its strength and economy.

PTFE

- Polytetrafluoroethylene is a polymer similar to polyethylene, in which hydrogen atoms have been replaced by fluorine atoms. The main property of this material is that it is practically inert, it does not react with other chemical substances except in very special situations. It has a very low coefficient of friction and great impermeability, also maintaining its qualities in humid environments.

- It is also a great electrical insulator and extremely flexible, it is not altered by the action of light and is capable of withstanding temperatures from –270 ° to 270 ° C. Its best known quality is non-stick.

TFE

- Tetrafluoroethylene is a chemical compound made up of carbon and fluorine. It is used as a raw material in the industrial preparation of polymers.

PMMA

- Polymethylmethacrylate is a brittle material that shows good mechanical strength, tensile strength and toughness. It is also a scratch resistant and easy to polish material. It has good resistance to temperature and stability to UV rays.

- Its main applications are in the food industry, advertising and exhibition.

PP

- Polypropylene shows high mechanical and tensile strength. It resists impact and is easy to weld.

- At sub-zero temperatures it can become brittle. The thermal and electrical properties are very good.

- Its main applications are: Pumps, valves, gaskets, toy parts, etc.

PLA

- Polylactic acid is a biodegradable polymer derived from lactic acid. It has properties similar to those of polyethylene and is resistant to moisture and grease.

PHA

- Polyhydroxyalkanoate is a biodegradable polymer produced by bacteria, it can be thermoplastic or elastomeric with melting points between 40º and 180º depending on its chemical composition. It is a material similar to Polypropylene in terms of properties.

PVC

- Polyvinyl chloride is a material with exceptional chemical, mechanical and tensile strength.

- It has good properties as an electrical insulator and is fire-retardant and self-extinguishing.

- Some of its main applications are: bearing cages, pipes, coating for electronics, etc.

PVDF

- Polyvinylidene fluoride exhibits high mechanical, tensile and pressure strength and low temperature toughness. It is self-extinguishing and has a high resistance to chlorine, bromine and high energy radiation.

- Its main applications are gaskets, pumps, rotating discs, valves, sliding accessories, sprockets, etc.

PA

- Polyamide exhibits high thermostability, rigidity, toughness and resistance, has good sliding and damping properties, and has good chemical stability against organic and combustible solvents.

- Its main applications are parts of bearings, sprockets, slide rails, wheels and accessories.

PE

- Polyethylene (Durogliss®) shows good chemical resistance to almost all acids and bases, detergents and hot water, its electrical and dielectric properties are very good and it has high toughness even at low temperatures.

- Its main applications are transport containers, pumps and valve parts, gaskets, sliding profiles and components for the food industry.

PFA

- Perfluoroalkoxy is a transparent thermoplastic material with a light blue sheen.

- The material combines many of the properties of PTFE and FEP. It is often used when clarity, flexibility, and a higher continuous operating temperature range are required.

PSU

- Polysulfone shows great thermal stability, has high mechanical strength, very good dielectric properties and resistance to hydrolysis, and high resistance to radiation.

- Its main applications are: parts of microwave ovens, dryers, humidifiers, food industry, pump wheels, insulation and medical industry.

PPSU

- Polyphenylenesulfon exhibits high resistance to all types of radiation, chemical resistance, impact and rigidity. It has good dimensional stability and its applications are similar to those of the PSU but presenting better chemical resistance.

PS

- Acrylonitrile butadiene copolymer exhibits good thermal and dimensional stability and high impact resistance. This material has good mechanical strength and toughness and is not weather resistant.

- Its main applications are parts that require high impact resistance also at low temperatures.

ECTFE

- Además de unas muy buenas propiedades deslizantes, el etilen-clortrifluoroetileno exhibe una extraordinaria resistencia al impacto incluso en temperaturas extremas.Muestra también, una alta resistencia a la radiación, químicos y al clima.

- Debido a la pureza de este material, se aplica en el procesamiento de químicos y agua ultrapura en la indústria de semiconductores.

- Otras aplicaciones comunes son: piezas que entran en contacto con materiales agresivos, revestimiento de tanques,bombas, bridas, accesorios, piezas en centrífugas e industria de ingeniería de control.

FEP

- A pesar de su suavidad el Etileno-propileno fluorado es químicamente inerte y tiene una constante dieléctrica baja en un amplio rango de frecuencias. Ofrece un grado muy alto de resistencia al agrietamiento por tensión, un bajo coeficiente de fricción, propiedades dieléctricas excepcionales y resistencia al calor.

- Es altamente transparente, con buena transmisión de longitudes de onda ultravioleta y visible. Resiste a largo plazo y tiene una excelente resistencia al ozono y la luz solar. Su índice de refracción es el más bajo de todos los termoplásticos y su reflejo de luz es bajo (igual que el agua).

- Las aplicaciones típicas de FEP incluyen revestimientos para tuberías y equipos de procesamiento químico, cubiertas de rollos, cables de aeronaves, cables de cámara, cables de alarma contra incendios y cables de registro de pozos.

PCTFE

- El Policlorotrifluoroetileno combina propiedades físicas y mecánicas, no inflamabilidad, resistencia química, absorción de humedad casi cero y excelente. Las propiedades eléctricas no se encuentran en ningún otro fluoropolímero termoplástico que también tenga un buen rendimiento en un rango de temperatura de -400 ° F a 400 ° F. PCTFE también tiene una alta resistencia a la compresión, una resistencia excepcional al flujo en frío y es ópticamente transparente. Debido a que PCTFE es una resina altamente fluorada, no es inflamable y resiste la mayoría de los químicos corrosivos. También mantiene su excelente capacidad de aislamiento eléctrico a través de ciclos térmicos y en entornos de alta humedad. La alta resistencia a la compresión y la estabilidad dimensional del producto lo convierten en una buena opción para material estructural, mientras que su muy baja tasa de desgasificación y permeabilidad hacen de PCTFE una buena opción para aplicaciones de instrumentación, laboratorio, aeroespacial y de vuelo. Otras aplicaciones comunes incluyen criogenia, válvulas, sellos y películas para envases de alimentos y productos farmacéuticos.

PEI

- La polieterimida tiene una alta resistencia mecánica en relación con una buena resistencia química y térmica , muestra una estabilidad dimensional. Su fuerza de torsión única permite la sustitución económica de pequeñas piezas mecanizadas en acero.

- Algunas de sus aplicaciones son piezas para ingeniería eléctrica,industria alimentaria y en la construcción de aeronaves.

PES

- Las Polisulfonas son un tipo de polímeros de ingeniería con alta estabilidad térmica, oxidativa e hidrolítica. Este tipo de polímeros tiene una buena resistencia a ácidos inorgánicos diluidos, alcalinos, soluciones salinas,aceites y grasas. Son termoplásticos amorfos que pueden ser moldeados, conformados o extruidos en una basta variedad de formas. Su elevada biocompatibilidad y facilidad para ser esterililizados hace de las Polisulfonas un material adecuado para aplicaciones medicas e aplicaciones de contacto alimentario.

MATERIALES CON CERTIFICADOS AERONAUTICOS & INDUSTRIALES